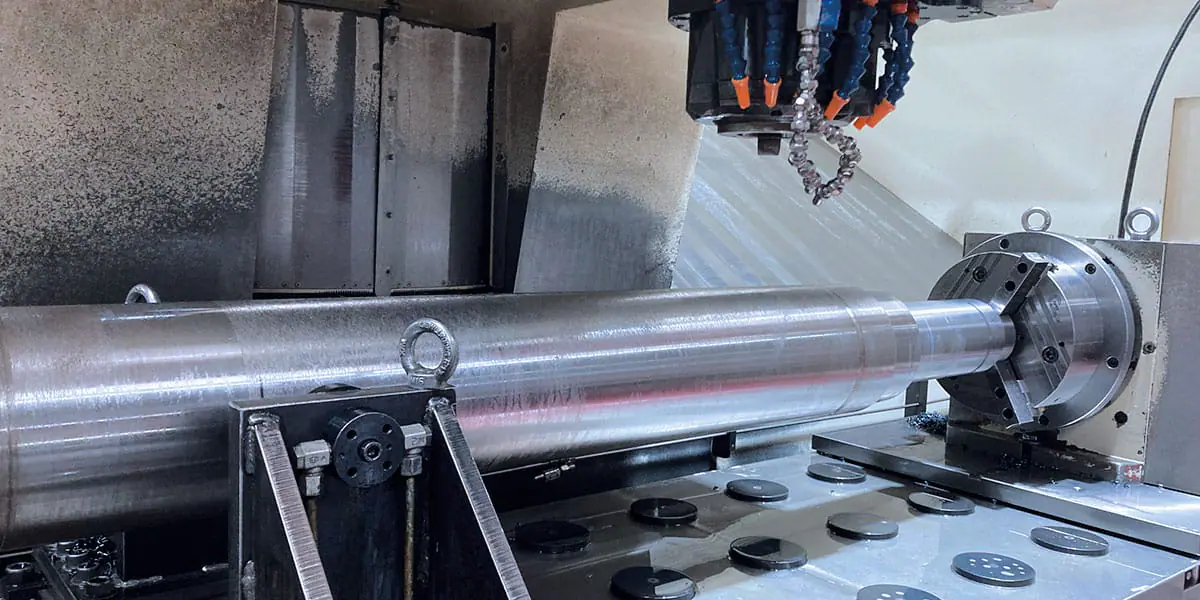

Production of a mixer shaft on a HEDELIUS CNC milling machine

Mixer shaft – contract manufacturing

Mixer shafts play a crucial role in a wide range of applications, from mechanical engineering to crane construction. In this article, we will take a look at the mixer shaft manufacturing process and explore the benefits of outsourcing this complex task to experienced contract manufacturing companies. Find out more about the challenges in the production of high-precision mixer shafts and how collaboration with experts in contract manufacturing can lead to outstanding quality results.

The production of mixer shafts, especially for industrial applications, can be complex due to several challenges:

- Precise dimensional accuracy: Mixer shafts often need to have very precise dimensions and tolerances to ensure that they fit smoothly into the overall system. Precise dimensional accuracy requires highly developed production methods and quality controls.

- Material selection: Choosing the right material for the mixer shafts is crucial. Depending on the application and the loads involved, materials with specific mechanical properties must be selected to ensure durability and function.

- Complex geometries: Depending on the application, mixer shafts can have complex geometries that require sophisticated manufacturing techniques. Processing such moulds requires precision, specialised machinery and expertise.

Mixer shaft, milled octagon

Mixer shaft 3.25 metres long

Mixer shaft for large construction machines for processing building materials

Production of a mixer shaft on a HEDELIUS CNC milling machine. The mixer shaft is prepared on a CNC lathe, then the octagon is milled and the shaft is finished. The octagon is required for attaching the mixer blades

Special features:

Part length: 3,250 mm

Octagonal length: 2,700 mm

Weight: 330 kg

- Surface quality: The surface quality of the mixer shafts is important to minimise friction and ensure proper function. This often requires grinding or polishing processes.

- Wear resistance: Mixer shafts are often exposed to heavy loads and wear, especially in moving parts. The challenge is to ensure sufficient wear resistance to guarantee a long service life.

- Quality control: Due to the critical role of mixer shafts in mechanical systems, strict quality control is essential. Every finished mixer shaft must be checked for dimensional accuracy, surface quality, strength and other important properties.

Overall, the production of mixer shafts requires a combination of technical expertise, advanced manufacturing technology and precise quality control in order to successfully overcome the aforementioned challenges.

Metal contract manufacturing

Lingenhöle has specialised know-how and many years of experience in metal processing. We react flexibly and produce cost-efficiently. We guarantee fast delivery times thanks to state-of-the-art technologies and optimised production processes. Outsourcing turned and milled parts allows them to concentrate their internal resources on core competences while placing production in experienced hands.