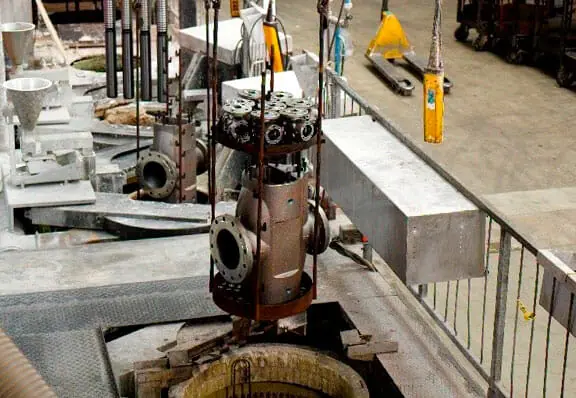

Salt Bath Nitrocarburising (Tenifer QPQ®)

In salt bath nitrocarburizing (salt bath nitriding), the components are treated in molten salt and then oxidized in a cooling bath. To optimize surface characteristics, the components can then be polished (blasted).

Advantages

- Increases durability

- Versatile, cost-efficient

- Significant increase in corrosion resistance with QPQ® treatment

Materials

- Casting materials

- Tool steels

Available plant sizes

- Length 1400 mm, Diameter 800 mm

Typical values for Salt Bath Nitrocarburising

Which materials can be plasma nitrided? What hardness and nitriding depth can be achieved? Here you will find an overview of typical hardness values of different material groups:

| DIN EN 10027-2 material number | DIN EN 10027-2 (Short) designation | Surface Hardness in Vickers [HV0,5] | max. Nitriding hardness depth (NHD) [mm] |

|---|---|---|---|

| Carbon steel | |||

| 1.0060 | E335 | 280-500 | 0,6 |

| 1.0577 | S355 | 280-480 | 0,6 |

| 1.1191 | C 45 E | 300-500 | 0,7 |

| 1.1221 | C 60 E | 300-500 | 0,7 |

| 1.5122 | 37MnSi5 | 300-500 | 0,6 |

| Tempered steel | |||

| 1.0762 | 44SMn28 (ETG 100) | 400-500 | 0,3 |

| 1.7033 | 34Cr4 | 500-600 | 0,5 |

| 1.7220 | 34CrMo4 | 500-600 | 0,5 |

| 1.7225 / 1.7227 | 42CrMo4 / 42CrMoS4 | 550-700 | 0,5 |

| 1.8159 | 50CrV4 | 550-700 | 0,5 |

| 1.8161 | 58CrV4 | 550-700 | 0,5 |

| 1.6582 | 34CrNiMo6 | 600-800 | 0,5 |

| 1.2710 | 45NiCr6 | 600-750 | 0,4 |

| 1.2312 | 40CrMnMoS86 | 650-800 | 0,3 |

| Case-hardening steel | |||

| 1.7131 / 1.7139 | 16MnCr5 / 16MnCrS5 | 600-750 | 0,5 |

| 1.7147 | 20MnCr5 | 600-650 | 0,4 |

| 1.5752 | 14NiCr14 | 500-650 | 0,4 |

| Nitriding steel | |||

| 1.8504 | 34CrAl6 | 900-1200 | 0,4 |

| 1.8507 | 34CrAlMo5 | 900-1300 | 0,5 |

| 1.8519 | 31CrMoV9 | 780-900 | 0,5 |

| 1.8550 | 34CrAlNi7 | 900-1100 | 0,5 |

| Ball bearing steel | |||

| 1.3505 | 100Cr6 | 450-700 | 0,25 |

| 1.2510 | 100MnCrW4 | 500-700 | 0,25 |

| Grey cast iron — nodular cast iron | |||

| 0.6025 | EN-GJL-250 (GG 25) | 300-450 | 0,3 |

| 0.7080 | EN-GJS-600 (GGG 60) | 450-600 | 0,4 |

| Stainless steel | |||

| 1.4006 | X10Cr13 | 900-1100 | 0,1 |

| 1.4021 | X20Cr13 | 900-1200 | 0,1 |

| 1.4034 | X40Cr13 | 900-1200 | 0,1 |

| 1.4122 | X35CrBo17 | 1000-1250 | 0,15 |

| 1.4571 | X10CrNiMoTi1712-2 | 900-1150 | 0,1 |

| Cold work steel | |||

| 1.2379 | X155CrMoV121 | 900-1200 | 0,15 |

| 1.2080 | X210Cr12 | 850-1150 | 0,15 |

| 1.2364 | X100CrMoV51 | 1000-1200 | 0,2 |

| 1.2601 | X165CrMoV12 | 900-1150 | 0,15 |

| 1.2436 | X210CrV12 | 700-900 | 0,15 |

| Hot work steel | |||

| 1.2343 | X38CrMoV51 | 900-1150 | 0,4 |

| 1.2344 | X40CrMoV51 | 900-1150 | 0,4 |

| 1.2567 | X30WCrV53 | 850-1050 | 0,3 |

| 1.2365 | X32CrMoV33 | 750-900 | 0,3 |

| High Speed Steel (HSS) | |||

| All qualities | 950-1400 | 0,02-0,15 | |

The maximum hardness is determined by the material. All statement without guarantee.

Downloads

Want to read up a bit? Need details? No problem, simply download the information you need.