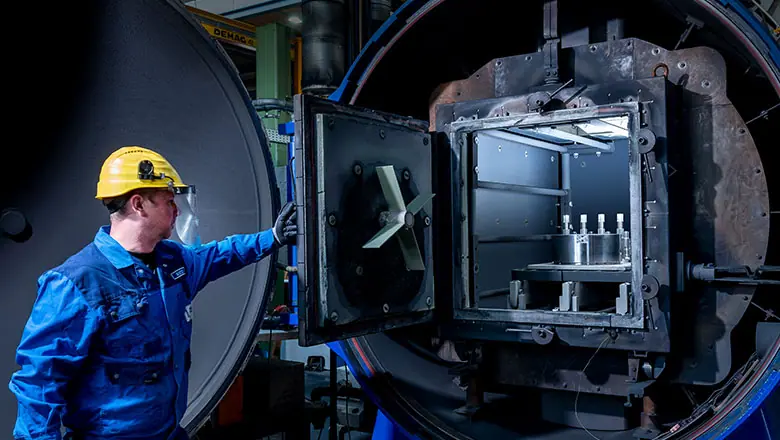

Vacuum Hardening

With vacuum hardening, the components are treated in a thick-walled furnace at a negative pressure of about 10–3 bar and at temperatures of between 800 and 1,200°C. The components are then quenched using inert gas at high pressure (4-6 bar). An optimal relationship between durability and toughness can be achieved by single or multiple annealing.

Advantages

- Minimal distortion

- No oxidation, smooth surfaces

- Reproducible results

- Decarburisation-free

Materials

- Cold and hot work steels

- High-speed steels

- Stainless steels

- Powder metallurgy steels

Available plant sizes

- Length 600 mm, diameter 900 mm, height 600 mm

Typical Values for Vacuum Hardening

What hardness can be achieved by vacuum hardening? Which materials are suitable for this? The overview shows commonly used steel grades for vacuum hardening as well as the achievable service hardness.

| DIN EN 10027-2 material number | DIN EN 10027-2 (short) designation (manufacturer brand name) | Service hardness [HRC] |

|---|---|---|

| Cold work steel | ||

| 1.2080 | X210Cr12 (K100) | 58-60 |

| 1.2083 | X40Cr14 (M310) | 52-54 |

| 1.2085 | X33CrS16 (M314) | 48-50 |

| 1.2311 | 40CrMnMo7 | 48-50 |

| 1.2312 | X36CrMnMoS86 (M200) | 48-50 |

| 1.2316 | X36CrMo17 (M303) | 45-47 |

| 1.2363 | X100CrMoV5 (K305) | 57-60 |

| 1.2379 | X155CrVMo12 (K110) | 61-63 |

| 1.2436 | X210CrW12 (K107) | 58-60 |

| 1.2550 | 60WCrV7 (K455) | 59-61 |

| 1.2631 | X50CrMoW911 | 57-59 |

| 1.2767 | X45NiCrMo4 | 54-56 |

| 1.2842 | 90MnCrV8 (K720) | 63-65 |

| 1.2884 | X210CrCoW12 | 59-61 |

| STM UNIVERSAL | 60-63 | |

| STM WOV 555 | 63-65 | |

| Hot work steel | ||

| 1.2342 | X35CrMoV511 | 48-50 |

| 1.2343 | X38CrMoV5-1 (W300) | 54-56 |

| 1.2344 | X40CrMoV5-1 (W302) | 53-55 |

| 1.2367 | X38CrMoV5-3 (W303) | 52-54 |

| 1.2714 | 55NiCrMoV7 | 58-60 |

| High Speed Steel (HSS) | ||

| 1.3343 | HS6-5-2 C (S600) | 64-66 |

| 1.3355 | HS18-0-1 (S200) | 64-66 |

| Stainless steel | ||

| 1.4021 | X20Cr13 (N320) | 46-48 |

| 1.4034 | X46Cr13 (N540) | 53-55 |

| 1.4112 | X90CrMoV18 (N685) | 55-58 |

| 1.4122 | X39CrMo17-1 (N335) | 47-49 |

| 1.4125 | X105CrMoV17 (N695) | 58-60 |

| 1.4528 | X105CrCoMo18-2 (N690) | 57-60 |

| Powder metallurgy high speed steel | ||

| 1.3377 | HS 3-3-4 (ASP 2005) | 62-64 |

| 1.3352 | HS 4-3-8 (ASP 2053) | 64-66 |

| 1.3345 | HS 6-5-3 (ASP 2023 / S790) | 62-64 |

| S290 | 64-67 | |

| 1.3344 | PM 6-5-3 | 63-65 |

| 1.3202 / 1.3253 | S390 PM | 64-67 |

| STM EWRA | 64-66 | |

| SPM 23 | 64-66 | |

| SPM 150 | 63-65 | |

| CPM 10 V | 62-64 | |

| CPM 15V | 62-64 | |

| CPM 3V | 61-63 | |

| CPM Rex 121 | 68-70 | |

| CPM Rex T15 | 61-63 | |

The maximum hardness depends on the cross-section. All statement without guarantee.

Downloads

Want to read up a bit? Need details? No problem, simply download the information you need.