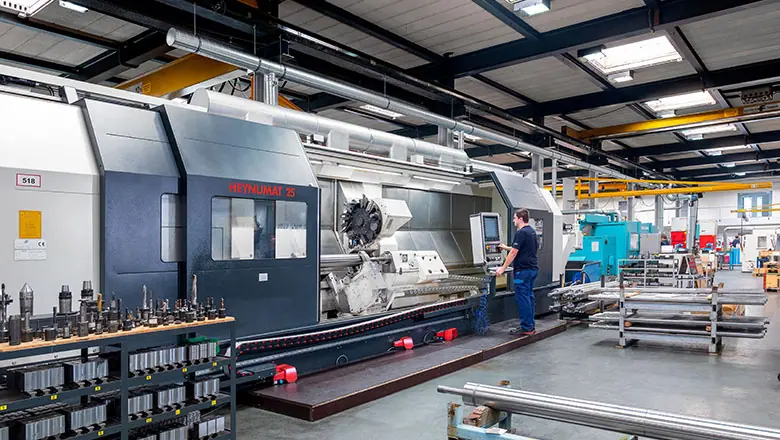

Large turned parts up to 6000 x 820 mm from the CNC turned parts manufacturer in Austria

CNC turned parts

Lingenhöle supplies ready-to-install precision turned parts: cost-efficient, on time and in optimum design. We attach great importance to quality assurance. Every single turned part undergoes strict inspection procedures to ensure that it meets the highest standards Our dedicated specialists work for your success from the drawing to the finished turned part.

Turned parts in contract manufacturing

For CNC turning, Lingenhöle Technologie uses only cutting-edge technology. The range of services extends from 50 mm to 6000 mm machining length, from the initial sample to series production. As an experienced CNC turned parts manufacturer, we turn complex geometries with tight tolerances as well as large turned parts in contract manufacturing. Your needs are important – and we have the right machines to meet these needs.

CNC turned parts Material

Thanks to modern machines and advanced tools, there are few limits to the materials that can be used today.

Turned parts made of steel

- Free-cutting steel

- Tool steel

- C-steel

- Stainless steel

- Powder steel

- Castings

- Casting blanks

Turned parts made of aluminium

- AlCuMgPb

- AlMgSi0,5

- AlmgSi1,0

- AlMg3

- Billetaluminium

- Aluguss

Turned parts made of brass and copper are also part of our portfolio.

Turned parts for your industry and application

Turned parts of the highest quality, delivered on time for a wide range of industries. No matter in which area you are looking for a partner for precise manufacturing solutions: As experts in the production of turned parts, we are active in machine, plant and tool construction, for example. We work for the paper industry and the shipping industry or for manufacturers of plastic injection moulding machines. rain columns and nuts, gear shafts, hollow shafts, motor shafts, drive shafts, toothed shafts or axle journals are turned.

Turned Parts Dimensions

Machining area for large turned parts up to a length of 6000 mm and a diameter of 475 mm.

| Make | Type | Turning ⌀ Steady Rests ⌀ |

Peak width | Spindle Bore | Power | Special Equipment |

|---|---|---|---|---|---|---|

| Heyligenstaedt Heynumat 25 UK |

CNC | to 820 45-310 |

6000 | 102 | 60 kW | C-axis, TRANSMIT powered tools, 2 steady rests and tailstock, program controlled |

| Heyligenstaedt Heynumat 21 UK |

CNC | to 570 45-310 |

3000 | 117 | 60 kW | C axis, TRANSMIT powered tools, steady rest and tailstock, program controlled |

| Index GU 3000 | CNC | to 450 20-165 |

3000 | 100 | 37 kW | Powered tools, steady rest and tailstock, program controlled |

| Index GU 1400 | CNC | to 220 50-200 |

1400 | 100 | 37 kW | Powered tools, steady rest and tailstock, program controlled |

| Index GU 800 | CNC | to 220 | 800 | 65 | 36 kW | Powered tools, tailstock, program controlled |

| Index GE 65 | CNC | 10-200 | 340 | 65 | 30 kW | Powered tools, bar feeder |

Downloads

Want to read up a bit? Need details? No problem, simply download the information you need.